Linear guides and ball screws are both crucial components in motion systems, but they serve different purposes and function in distinct ways. Here’s a comparison to highlight their differences:

1. Purpose and Function

-

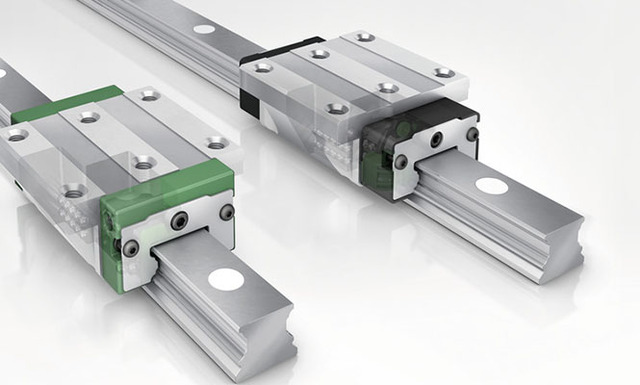

Linear Guide:

- Function: Provides linear motion with minimal friction and high accuracy. It supports and guides a moving component (like a carriage) along a straight path.

- Usage: Commonly used in applications requiring precise linear movement, such as CNC machines, 3D printers, and automated assembly systems.

-

Ball Screw:

- Function: Converts rotary motion into linear motion. It uses a screw mechanism with ball bearings that roll between the screw and nut to minimize friction and provide smooth, precise movement.

- Usage: Often used for applications where accurate and efficient linear motion is required, such as in machinery that needs to move a load with high precision and force.

2. Motion Type

-

Linear Guide:

- Motion: Provides linear movement along a straight path. The movement is typically guided by a rail and carriage system with rolling elements (e.g., ball bearings or rollers) to reduce friction.

-

Ball Screw:

- Motion: Translates rotary motion from a motor into linear motion. The screw rotates, and the nut moves linearly along the screw, transferring rotary motion into linear displacement.

3. Load Handling

-

Linear Guide:

- Load Handling: Handles loads in multiple directions (including radial, axial, and moments) depending on the design. They are designed to support heavy loads and maintain precision.

-

Ball Screw:

- Load Handling: Primarily handles axial loads. The design is focused on translating rotational force into linear movement, and the load is distributed along the screw shaft.

4. Accuracy and Precision

-

Linear Guide:

- Accuracy: Provides precise linear guidance and positioning. The accuracy depends on the quality of the guide and the system’s alignment.

-

Ball Screw:

- Accuracy: Provides high accuracy in converting rotary motion to linear motion. Precision is affected by factors such as screw pitch, lead accuracy, and the quality of the bearing system.

5. Speed and Efficiency

-

Linear Guide:

- Speed: Suitable for a wide range of speeds depending on design and application. Friction and wear are minimized through the use of rolling elements.

-

Ball Screw:

- Speed: Efficient at high speeds and can be designed to handle rapid movements. The efficiency of converting rotary to linear motion is high, which reduces power consumption.

6. Maintenance and Durability

-

Linear Guide:

- Maintenance: Requires regular maintenance, including lubrication and checking for wear. Some designs are more resistant to contaminants and require less maintenance.

-

Ball Screw:

- Maintenance: Also requires regular maintenance, including lubrication. Ball screws can be sensitive to contamination and need to be kept clean to avoid wear and damage.

7. Integration

-

Linear Guide:

- Integration: Typically mounted to a base or frame and supports a moving component. It is used in conjunction with other components for linear motion.

-

Ball Screw:

- Integration: Integrated into a drive system where a motor rotates the screw. It is often used with linear guides to convert and guide motion precisely.

Summary

- Linear Guide: Primarily used for guiding linear motion with high precision and minimal friction.

- Ball Screw: Used for converting rotary motion into linear motion with high efficiency and precision.

In many systems, both components are used together to achieve precise and reliable linear motion. For example, a CNC machine might use linear guides to support the moving parts and ball screws to drive those parts with precise control.