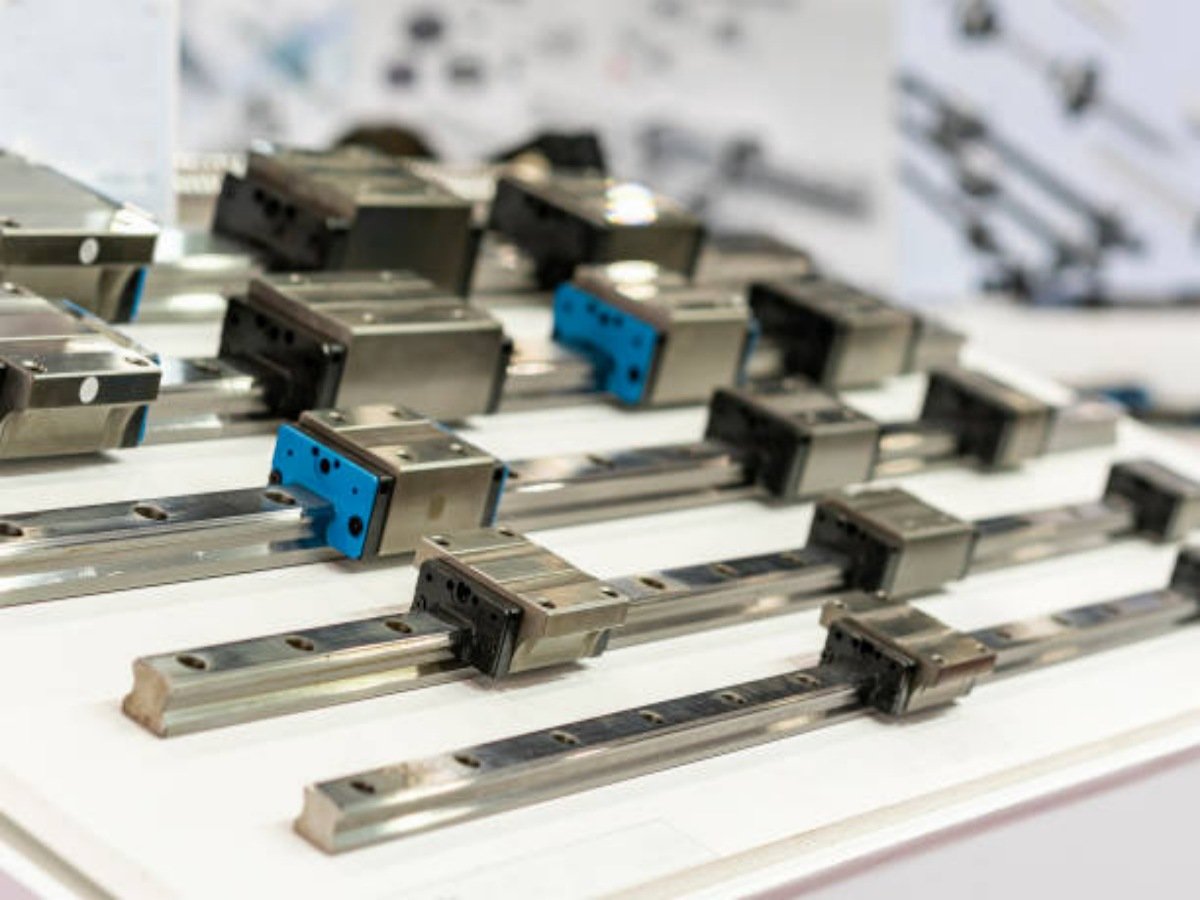

What are Linear Guide Rail Bearings?

Linear guide rail bearings are mechanical components that facilitate smooth and precise linear motion in various applications. They are designed to support and guide loads in a linear direction, minimizing friction and enhancing the overall performance of the system. These bearings play a crucial role in industries such as manufacturing, automation, robotics, and transportation.

Types of Linear Guide Rail Bearings

There are several types of linear guide rail bearings available in the market, each suitable for specific applications. The most common types include:

1. Ball Bushing Bearings

Ball bushing bearings, also known as linear ball bearings, are designed with recirculating balls that provide low-friction and smooth linear motion. They offer high load capacity and excellent accuracy, making them ideal for applications that require high precision.

2. Roller Guide Bearings

Roller guide bearings utilize cylindrical rollers to support and guide loads. They offer higher load capacity than ball bushing bearings and are suitable for heavy-duty applications. Roller guide bearings are commonly used in machine tools, industrial equipment, and automation systems.

3. Slide Guide Bearings

Slide guide bearings, also known as plain bearings, use sliding surfaces to facilitate linear motion. They are cost-effective and require minimal maintenance. Slide guide bearings are commonly used in low-load and low-speed applications.

Advantages of Linear Guide Rail Bearings

Linear guide rail bearings offer numerous advantages over other types of bearings. Some of the key benefits include:

1. High Precision

Linear guide rail bearings provide precise and accurate linear motion, ensuring that the system operates with minimal error. This makes them ideal for applications that require high precision, such as CNC machines and measuring equipment.

2. Smooth and Quiet Operation

Thanks to their low-friction design, linear guide rail bearings offer smooth and quiet operation. This is essential in applications where noise reduction is important, such as medical devices and optical systems.

3. High Load Capacity

Linear guide rail bearings are capable of supporting heavy loads while maintaining their smooth motion. This makes them suitable for applications that involve moving large objects or heavy machinery.

4. Long Service Life

With proper maintenance, linear guide rail bearings can have a long service life. Their robust construction and high-quality materials ensure durability and reliable performance, even in harsh environments.

Installation and Maintenance

Proper installation and maintenance are crucial for maximizing the performance and longevity of linear guide rail bearings. Here are some important points to consider:

1. Cleanliness

Ensure that the installation area is clean and free from dirt, debris, and contaminants. This helps prevent premature wear and damage to the bearings.

2. Lubrication

Apply the appropriate lubricant to the bearings to minimize friction and reduce wear. Regularly check and replenish the lubricant as needed.

3. Alignment

Ensure that the linear guide rail bearings are properly aligned to avoid excessive stress and uneven wear. Use precision tools and follow the manufacturer's guidelines for alignment.

4. Inspection

Regularly inspect the linear guide rail bearings for signs of wear, damage, or misalignment. Replace any worn or damaged bearings promptly to prevent further issues.

Conclusion

Linear guide rail bearings play a crucial role in various industries, offering high precision, smooth operation, and long service life. Understanding the different types of linear guide rail bearings and their advantages can help you choose the right bearings for your application. By following proper installation and maintenance practices, you can ensure optimal performance and durability of your linear guide rail bearings.