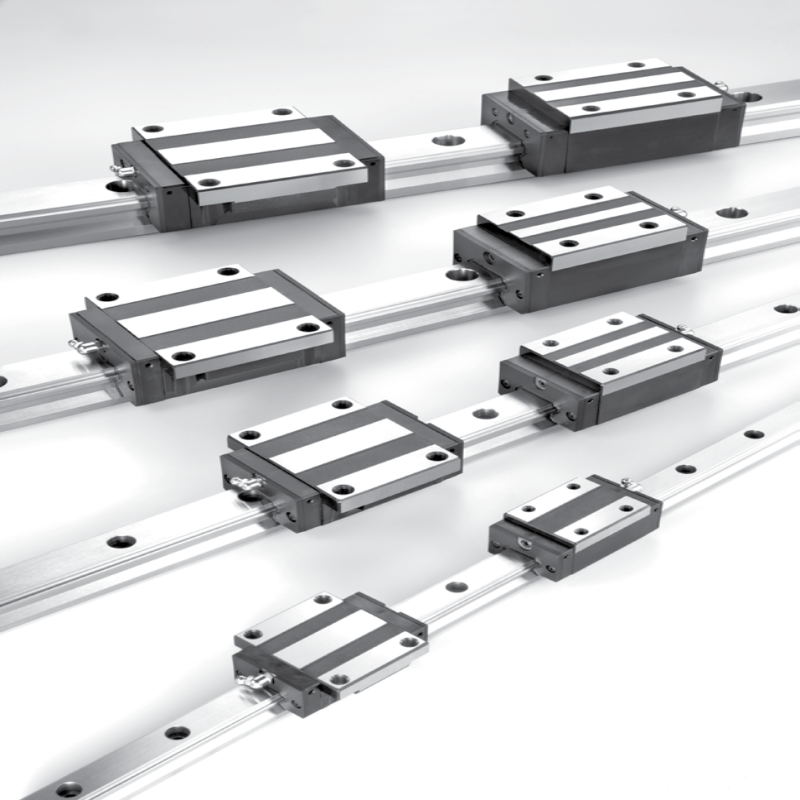

Reliable Linear Motion in Packaging Machinery

In the dynamic landscape of the packaging industry, downtime poses a significant challenge to productivity. However, by opting for robust linear motion components, many potential sources of downtime can be effectively eliminated. These resilient guides and positioning tables are engineered with design features that mitigate premature failure caused by inadequate lubrication practices or contamination, while still meeting the escalating demands for accuracy, precision, and load capacity in packaging applications.

Here's a brief overview of three essential features to consider when aiming to maximize the lifecycle of linear guides and positioning tables in demanding packaging environments:

-

Self-Lubrication for Maintenance-Free Operation: Inconsistencies or inadequacies in lubrication are common culprits behind premature linear guide failure, leading to costly downtimes. Moreover, the use of lubricants can be challenging in packaging machinery, particularly those in direct contact with packaged products. Hence, it's crucial to opt for linear motion products equipped with internal lubrication mechanisms. While various self-lubricating linear guides exist, not all offer the same level of effectiveness. Our C-Lube lubrication technology stands out by integrating oil-impregnated lubricating elements within the slider housing, ensuring maintenance intervals of up to 5 years or 20,000 km of operation.

-

Focus on Contamination Reduction: Packaging applications are highly sensitive to contamination, which can jeopardize product integrity and disrupt productivity. Contaminants, such as cardboard particles, are prevalent in packaging plants and can bring production lines to a halt if they infiltrate linear guides. To combat this, linear guides with sealing capabilities, such as our Ultra Seal technology, provide durable elastomer seals to safeguard against contaminants. Additionally, precision grinding of rail surfaces ensures optimal sealing effectiveness.

-

Consideration of Clearance-Type Bearings: While preloading linear bearings is common in applications requiring maximum accuracy and stiffness, packaging machinery often benefits from clearance-type guides and motion stages. By incorporating some clearance between the rail and rolling elements, these guides require less linear force to move the slider, facilitating smoother operation in fast-moving packaging machines without compromising accuracy and precision.

Selecting linear bearings that offer self-lubrication, contamination resistance, and clearance can mitigate certain downtime issues, ensuring smooth and efficient operation of linear motion axes over the long term.

For further insights into Shundu's comprehensive range of bearings and linear motion solutions, please visit [our website].